Jets and Pressure

Printed From: Carpet Cleaning Forum

Category: Carpet Cleaners Discussion

Forum Name: Carpet Cleaning Tips and HOW-TO-SECTION

Forum Description: Periodically KK gives you a new tip. Add one of your own if you wish

URL: https://www.kleenkuip.com/forum/forum_posts.asp?TID=686

Printed Date: 28/December/2025 at 5:02am

Software Version: Web Wiz Forums 12.06 - https://www.webwizforums.com

Topic: Jets and Pressure

Posted By: carpetologist

Subject: Jets and Pressure

Date Posted: 20/October/2004 at 1:46pm

|

Jets and Pressure An ongoing debate in the cleaning industry has existed since the beginning of "steam" cleaning concerning the size and number of jets used to apply the cleaning solution to the carpet and the pressure at which it should be applied.

The next number on the jet is the size of the orifice which determines the amount of solution which can be sprayed at any given pressure. Usually, these go from 02 to 14. They are engineered so that they are cumulatively equal. For example, three #02 jets will equal the output of one #6 jet or two #4 will equal one #8, and so on. The final digit may be a letter E. This means the flow is even across the entire width of the fan. If there is no letter E, the fan will be tapered to allow for the overlap of multiple jets. The amount of total volume delivered by the jets is expressed in gallon per minute or GPM. For simplicity let's take a single jet wand and vary the pressure. Since a truck mounted unit will need about 1-1/2 GPM to operate efficiently, any variation in pressure results in a need to change jets. For example, at 500 lbs. pressure, we use a #04 jet, at 400 lbs. a #06 jet and at 300 lbs. a #08 jet. The volume remains about the same but the velocity and size of the solution droplets change. This can affect the agitation from the solution pressure and the amount of heat carried to the fibers in the form of droplets. The smaller the jet, the smaller the droplet and the less heat it can carry. Put your wand over a bucket and pull the trigger for 60 seconds. The amount of solution delivered in gallons will be your GPM. Portables should flow at 1-1/4 maximum GPM. ------------- Kleen Kuip Supply Mart Inc. http://www.kleenkuip.com - New & Used Professional Carpet Cleaning Machines, Restoration Equipment, Training, Service and Supplies |

Replies:

Posted By: billy196628

Date Posted: 28/December/2006 at 2:56pm

|

ok now we have a blue line thernalwave 2.

the wand it came with has 4 jets size 4 tips now if we go to a size 2 tip will this cause a problem less water per min and less temp . will a higher presure help I do not mean over 400 psi when we set the presure for carpet . it,s just after you prespray and clean you are puting so much water in and in the winter thats not a good thing. summer no problem . |

Posted By: EricValentine

Date Posted: 28/December/2006 at 7:49pm

|

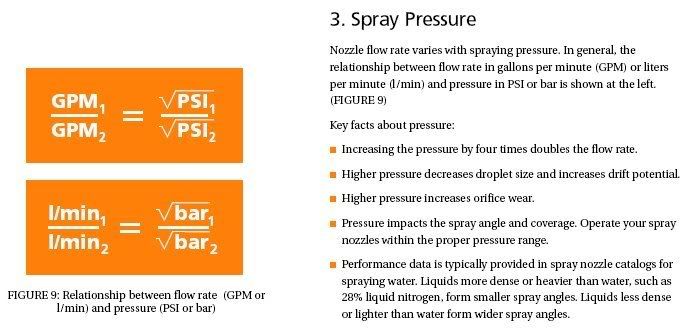

Four times the pressure will double the flow.

This was taken from the teejet website's users guide to spray nozzles

------------- If you are in the Las Vegas area, I am always up for lunch. 702-985-6214 |

Typical is the "T" jet illustrated. Reading from the left you may find the letters SS indicating a stainless steel jet. Otherwise they are usually brass. The first 2 or 3 numbers will represent the spread angle of the fan jet. The angle 80вк, 90вк, 110вк, etc. plus the height above the carpet will determine the width of the fan when it strikes the pile. As an example, with a 90вк fan (the simplest angle to calculate) the spread of the fan will always be twice the height above the surface. For example, a 90вк jet 5 inches above the carpet will cover a width of 10 inches. The further the jet is from the surface, the wider the fan, and of course, the closer, the narrower the fan. On multiple jets, each jet only covers a fraction of the total width desired.

Typical is the "T" jet illustrated. Reading from the left you may find the letters SS indicating a stainless steel jet. Otherwise they are usually brass. The first 2 or 3 numbers will represent the spread angle of the fan jet. The angle 80вк, 90вк, 110вк, etc. plus the height above the carpet will determine the width of the fan when it strikes the pile. As an example, with a 90вк fan (the simplest angle to calculate) the spread of the fan will always be twice the height above the surface. For example, a 90вк jet 5 inches above the carpet will cover a width of 10 inches. The further the jet is from the surface, the wider the fan, and of course, the closer, the narrower the fan. On multiple jets, each jet only covers a fraction of the total width desired.